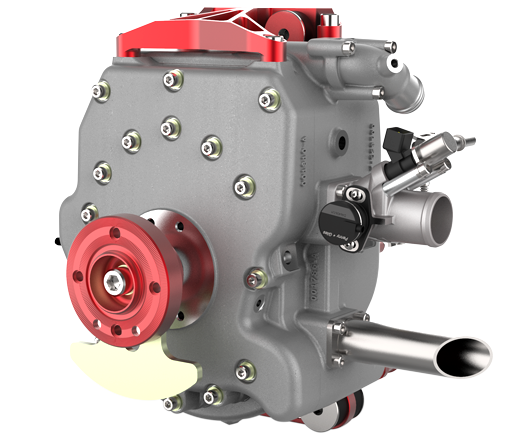

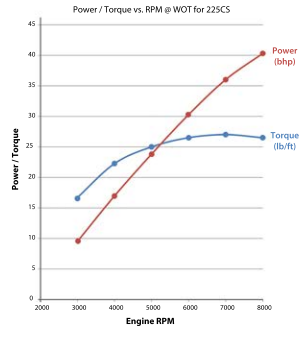

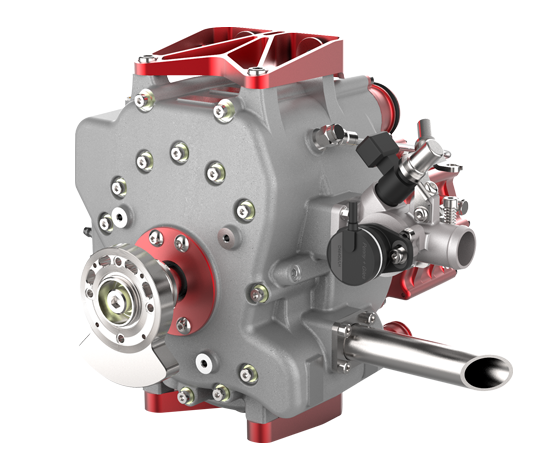

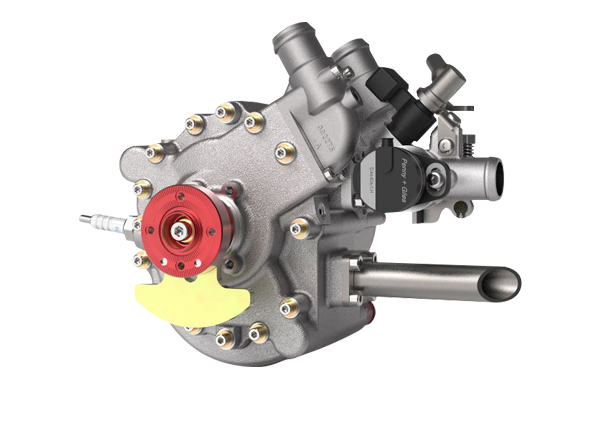

225CS – 40 BHP

This world-class 225CS – 40 BHP rotary engine delivers market-leading performance in terms of power, weight, efficiency, and reliability.

Please contact HFE International to discuss how this engine fits your application, and for pricing information.

- Description

- Additional information

Description

The 225CS engine is a compact and lightweight engine making it easy to integrate into a wide range of applications. You’ll benefit from a market-leading power to weight ratio with the 225CS generating 40bhp but weighing just 10kg.

Key Benefits of Wankel Rotary Engines:

- Clean

- Multi-fuel

- Compact

- Low vibration

- Long endurance

- Few moving parts

- High power-to-weight

- Low total cost of ownership

- Revolutionary cooling system

About AIE UK:

Advanced Innovative Engineering (AIE), UK Ltd. designs and develops heavy-fuel Wankel rotary engines and propulsion systems for unmanned aircraft and auxiliary power units.

Offering a full-spectrum capability from concept to production, AIE applies over 100 years of experience developing rotary engines that deliver greater power in a smaller, lighter package.

When you choose an AIE engine you’re getting all the benefits of a Wankel rotary engine – more power, less weight, fewer vibrations – combined with the advantages of AIE’s patented SPARCS technology.

Patented SPARCS technology means your engine is lighter, will use less oil, and will last longer. The total cost of ownership is reduced, you get a larger payload capacity, and improved endurance.

HFE International is proud to serve as an engine sales and services provider for AIE’s range of advanced rotary propulsion systems.

Please contact us to discuss how this engine fits your application, as well as pricing information.

Additional information

| Engine Type | Single Rotor |

|---|---|

| Displacement | 13.7 cu in (225 cc) |

| Compression Ratio | 9.6:1 |

| Fuel Type | AVGAS / Gasoline / Heavy Fuels |

| Power Output | 40 bhp (30 kW) |

| Weight | 22 lbs (10 kg) Core Weight |

| Cooling | Liquid Cooled Patented SPARCS |

| Ignition System | Twin Spark Plug |

| Engine Control System | Full Electronic Engine Management |

| Oil System | Digitally Optimized Lubrication |

| Configuration | Pusher / Tractor |

| Options | Generator |

| Time Between Overhaul | 500+ hours |